Using storage flexibility without operational risks

Most heating companies use accumulators for flexibility in their operations. However, charging and discharging them can be challenging. The network, electricity prices and production schedule impact when and how flexibility is available

Renewable integration in district heating challenges

Heating companies are introducing renewables to replace their fossil sources, both at central and decentral locations throughout their network. However, it is often challenging to maximise their use and not be dependent anymore on the safe base loads that fossil sources have provided throughout the past decades.

District heating companies are undertaking various hardware and software measures to achieve operational and economic stability during this transformation. Accumulators (also known as thermal storages or buffers) have become a main asset to build flexibility and some operational margins into the daily operations of district heating.

Next to a main target for heating companies to increase the renewable share in production with these accumulators - they provide the opportunity to enter a new revenue stream of more flexibility in electricity trading.

However, taking the step from just operating an accumulator for a higher share of renewable energy to making the most of its flexibility for various purposes has been proven challenging.

What is the best time to charge and discharge?

To leverage all possible accumulator benefits, many questions need to be answered. When is the most optimal time to charge and discharge your accumulator? And what source is charging the accumulator with what temperature – and how much energy will be stored?

This boils down to more than ensuring that your accumulator isn't empty just when you need additional energy in case of a morning peak. In the worst-case scenario, a company may just have emptied its accumulator and subsequently experience a demand peak while renewable heat sources are already at their maximum capacity.

Often, the most expensive and polluting sources, like peak boilers, are then used as the last resource since they are the only ones that can ramp up quickly enough. But, in fact, you don't want to sacrifice the flexibility for increasing E-trade profits by only using your accumulator as a safety margin during peaks.

Balancing and preventing those situations is just one of the many potential challenges district heating companies face with their accumulator optimisation. Currently, accumulator control is usually based on standard logic – for instance, charging at night and discharging during peak demand times.

While this approach builds some base level of stability, it doesn’t capture the full value companies could take from leveraging the flexibility accumulators offer.

Factors that determine the flexibility of your accumulator

What companies need is real-time insight in their accumulator, combined with end-to-end data that shows them when to do what. Here are three key factors that explain why this is key for accumulator success.

1. The network impacts how much heat is available in your accumulator

The temperature levels in your network at which heat is stored in the accumulator determine the amount of energy available in your storage. At the same time, the timing of demand peaks dictates the moment when you should start discharging your accumulator. This may look entirely different depending on the season – for example, winter vs. spring or autumn.

Another consideration is the hydraulic limitations (bottlenecks) around the accumulators location, which impact the maximum power it can deliver. If it’s a decentralised accumulator, that impact will even be greater.

2. External price signals change every day and throughout the year

When also using your accumulator to make use of the volatility of E-markets, the challenge of optimal accumulator control increases. Electricity prices are extremely volatile and prone to rapid changes - even during a single day.

Managing the E-dynamics and setting certain thresholds is not standardisable: per hour and per day, the price patterns on the electricity market change – making it extremely challenging to forecast.

Any company operating accumulators already knows that the most profitable times to produce and consume electricity are different every day. While ultimately, these electricity prices define the price of heat for your end-customer.

Ideally, when prices are high, it’s more resource-efficient to charge your accumulator with CHP heat and sell the electricity. And when electricity prices drop, charging the accumulator with a heat pump or e-boiler is a better approach.

Graphs: https://www.euroheat.org/news/using-storage-flexibility-without-operational-risks

3. Your production schedule changes daily based on your demand

A production schedule depends on demand, which changes every day based on factors such as outdoor temperature, the season of the year, a particular time such as public holidays, and many other weather-based and historical variables.

Considering these factors, it’s not always clear when to charge and discharge the accumulator for optimal performance. For instance, when is it better to charge it with renewable sources like a heat pump, geothermal or a CHP if a snowstorm is coming in the middle of the day and your demand increases?

Demand patterns set the boundaries for your production schedule, and the flexibility you gain from that determines the best time to charge the accumulator and with which source.

Also, your sources have different efficiencies at different loads. With an accumulator, your options to schedule loads in a smart way increase – but so does the difficulty of choosing the right one. For instance, do you maximise your heat pump load when low temperatures are demanded, increasing its COP – or are the electricity prices so high at that time that your CHP would be more cost-effective?

Knowing when to schedule which load to maximise overall efficiency is key.

The takeaway

To optimise the operation of thermal storage with flexibility and reliability in mind, you need to consider all the aspects of the heating system, from end-user demand and network dynamics to production schedule and electricity market volatility.

And since all these factors strongly depend on each other, and the conditions are changing every hour, it needs to be done in real time.

Optimise your accumulator using Gradyent’s Digital Twin

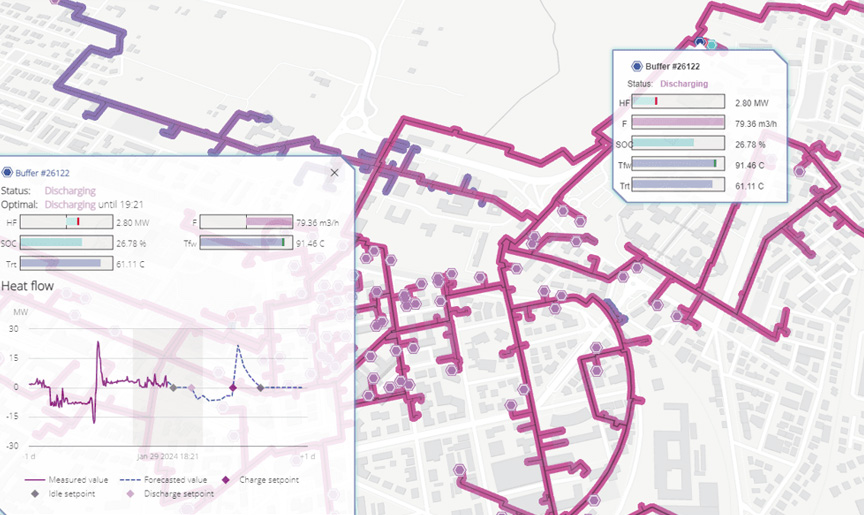

Recently, Gradyent has helped a district heating operator dynamically optimise temperatures for peak demands by providing a real-time, end-to-end view into their decentral accumulator.

With one of the objectives to reduce peak temperatures to lower overall heat losses, our Digital Twin solution forecasts supply temperatures as well as charging/discharging cycles at the same time. As a result, the amount of energy stored was maximised, and sudden supply peaks were avoided.

Graphs: https://www.euroheat.org/news/using-storage-flexibility-without-operational-risks